More About Copper Foil

Wiki Article

3 Simple Techniques For Copper Foil

Table of ContentsMore About Copper FoilGetting My Copper Foil To WorkSome Known Details About Copper Foil 4 Simple Techniques For Copper FoilCopper Foil Fundamentals ExplainedNot known Details About Copper Foil What Does Copper Foil Do?An Unbiased View of Copper FoilGet This Report on Copper Foil

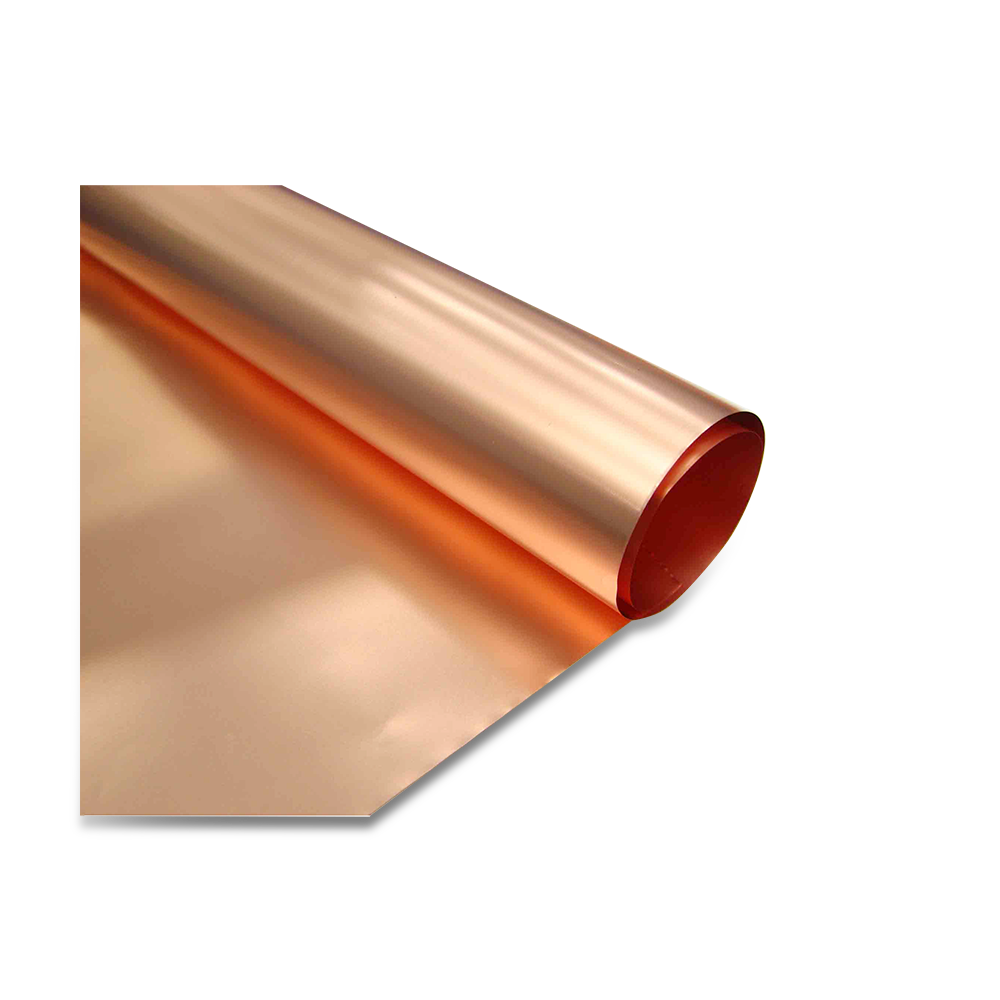

When you copper aluminum foil tarnished glass lots of concerns come up that you weren't educated just how to deal with. Scroll down to locate an entire list of answers to assist improve your stained glass copper hindering.There are architectural as well as visual selections to be made. If you go for the copper aluminum foil you'll be area on. 3/16" 1/4" aluminum foil functions well for most common copper aluminum foil discolored glass items. If you have a larger overlap you might find that the width of the solder is as well vast when you start constructing the assemble.

6 Easy Facts About Copper Foil Explained

What Does Copper Foil Mean?

The rolls fit completely and also when the lid is safeguarded in position, it helps maintain the aluminum foil. Beginning hindering away from the border of a piece When you copper aluminum foil stained glass it's ideal to begin hindering far from the outdoors edge as this produces more powerful adhesion. This is since the aluminum foil isn't joined outside edge where is is a lot more likely to find loose.

Do you understand just how to copper foil stained glass that is heavily textured? If you have actually attempted this you'll recognize that the foil breaks as you try to go from high to low. Despite shallow textured glass (surges) the foil occasionally breaks as it crosses the surges as opposed to perfectly contouring to it.

Not known Factual Statements About Copper Foil

Use a cork for kinking textured glass as it is softer and also offers stress while minimizing tearing. It cleans up the foil also!Better still, you can utilize a to get rid of the hefty structure on the glass prior to foiling. This truly aids with foil adhesion. Prior to you get a rippled little bit make certain it will certainly fit your mill. Usage lined paper to aid centre the copper foil When you copper foil stained glass by hand it can be difficult to centre the aluminum foil.

Copper Foil Things To Know Before You Buy

Use lined paper as an overview! This is an intriguing concern as well as one I obtain asked A GREAT DEAL. My solution could save you HOURS of time grinding as well as cleansing. When you copper aluminum foil stained glass you do not have to have a rough surface area for the foil to adhere to.Your shiny cut edges are find more fine without grinding. Just take care of your fingers. You can simply weaken the sharp sides off with a wet scythe rock to avoid cutting yourself and to avoid sharp sides cutting the aluminum foil. Ground sides require to be extensively cleaned prior to hindering. Occasionally when you copper foil stained glass the foil comes away from the side.

Not known Incorrect Statements About Copper Foil

If you solder as well gradually or go over the solder repetitively the foil adhesive thaws and also comes to be unstuck. It deserves keeping in mind that the adhesive exists to hold the foil in position until it's soldered. It doesn't serve to maintain it on as soon as it's been heated. Attempt raising the size of the outside aluminum foil a tiny bit as well.

If you tin the sides as opposed to developing a beaded side. "Tinning" implies covering them with a thin finishing of solder. "Beading" is a spherical side of solder that 'clings' to the edge of the discolored glass as well as is much more powerful. I have a video clip on exactly how to do a beaded side on this page. Discover More Here Be mild when cleaning and polishing.

Rumored Buzz on Copper Foil

There are much more solutions concerning copper aluminum foil not sticking below.Circuitry need is one of the most vital drivers for digital package option. The Semiconductor Industry Organization (SIA) (Sematech) publishes a file on a normal basis to recommend the sector of today and also future wiring demand for a variety of item types. Table 1 reveals parts of the table that was released in 1999 (copper foil).

Not known Facts About Copper Foil

Reduced I/O remain in hand held products that compromise on efficiency to accomplish their smaller size. These I/O worths are leading edge applications with the largest number of I/Os. Typical applications have a lot lower demand however gradually will certainly reach the cutting edge needs, which are 510 years ahead of the typical item.The other item of the I/O equation is the dimension of the chip. This is primarily a function of exactly how numerous circuits are being utilized by the application.

Our Copper Foil PDFs

In this method, a gold or aluminum wire is bound to a pad on the chip and then knotted to a pad on the chip copyright, which is the base for the module. A normal chip to substrate connection making use of cord bond is noted in Fig. 1. With distinct wires, their positioning can not be as well check here close or the wires will certainly touch each other.Report this wiki page